Traditional COB vs Flip Chip COB LED Technology: A Complete Guide

In the world of LED display and lighting solutions, COB (Chip on Board) technology has played a crucial role in shaping modern applications. Over the years, two major approaches have emerged—Traditional COB and Flip Chip COB. While both serve similar purposes, they differ significantly in design, performance, cost, and reliability. Let’s explore each in detail.

Traditional COB Technology

Traditional COB is a widely used method where LED chips are directly mounted on a PCB (Printed Circuit Board) with the help of wire bonding. These tiny gold or aluminum wires connect the LED chip to the circuit, while protective encapsulation safeguards the chip and ensures even light distribution.

Key Features of Traditional COB:

-

Cost-Effective: Uses mature manufacturing methods, making it suitable for cost-sensitive projects.

-

High Light Output: Enables high-density chip placement for brighter designs.

-

Thermal Limitations: Heat dissipation relies heavily on the PCB and external heat sinks, which may affect efficiency.

-

Reliability Concerns: Wire bonds can weaken over time due to thermal cycling and mechanical stress.

Applications: Street lighting, office illumination, residential fixtures, spotlights, and other cost-driven projects.

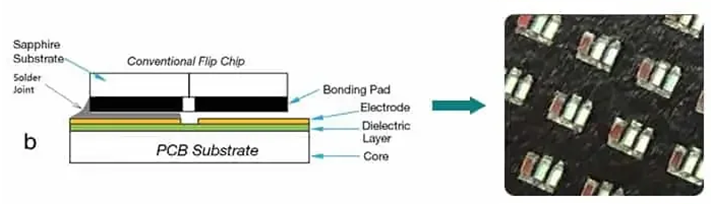

Flip Chip COB Technology

Flip Chip COB is an advanced method where LED chips are flipped upside down and mounted directly onto the PCB using solder bumps instead of wire bonds. This design ensures better heat dissipation and improved electrical efficiency.

Key Features of Flip Chip COB:

-

Superior Thermal Management: Direct chip-to-PCB contact reduces thermal resistance.

-

Higher Efficiency: Lower electrical resistance ensures brighter and more efficient performance.

-

Compact Design: No wire bonds mean more space for high-density chip placement.

-

Enhanced Reliability: Eliminates weak points caused by wire bonding.

Applications: High-performance lighting, advanced LED displays, floodlights, downlights, and premium projects where efficiency and durability are critical.

Traditional COB vs Flip Chip COB: A Comparison

-

Thermal Management: Traditional COB depends on PCB conductivity; Flip Chip COB offers direct heat transfer.

-

Electrical Performance: Wire bonding in traditional COB increases resistance; Flip Chip COB ensures higher efficiency.

-

Reliability: Traditional COB faces stress issues in wire bonds; Flip Chip COB enhances durability.

-

Cost: Traditional COB is more affordable; Flip Chip COB requires advanced manufacturing and is costlier.

-

Applications: Traditional COB suits general lighting; Flip Chip COB is best for high-end, performance-driven applications.

Conclusion

Both Traditional COB and Flip Chip COB technologies have their advantages. For cost-effective LED applications, traditional COB remains a reliable choice. However, for high-performance, compact, and durable LED solutions, Flip Chip COB leads the way.

At AET Displays, we specialize in delivering advanced COB LED display and lighting solutions that balance cost, efficiency, and performance.

📩 For product inquiries, visit aetdisplays.com or email us at sales@aetled.com.

🔗 Stay updated: AET Displays LinkedIn

Comments

Post a Comment